Norske Shell – Stavanger Jun ’06 – Dec ’15

Stones Development in GOM –FEED & execution

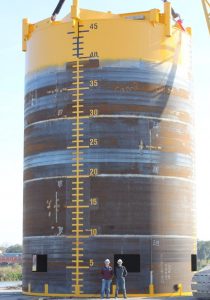

Involved in the FEED, tender evaluation and execution phase of the project. Responsible for functional specification within the structural discipline SOW, selection of engineering standards and setting up the job with the contractor to deliver the work to GOM standards. I was assigned as structural delivery lead for the 32ft OD foundation suction pile supporting the pump station.This is the largest diameter pile to be installed to date, transported vertically and installed at 0.6deg tilt. By challenging the requirement for pre-installed levelling frame proposed by pump supplier I achieved significant weight and cost saving for the company. Responsible for lift padeye verification checks, installation guides and pile design checks. In addition I was responsible for the design verification of the pump station protection structure, PCM and the manifold piping. Awarded Stones recognition award for the work done.

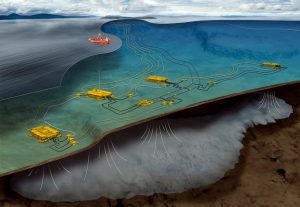

Draugen Infill Project – detailed design

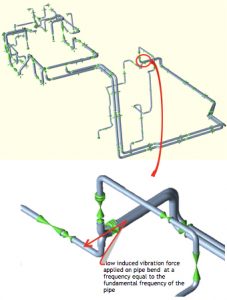

Lead structural engineer in the hardware team responsible for the assurance of the design of Rogan South manifold, and the associated manifold piping using CAESAR II. Verification of pump station and the protection structure with specific focus on the design against HISC failure and flow induced vibration. I performed HISC fit for service assessment to DNV F112 of the existing termination head compact flange using Ansys non-linear capability to justify this high value asset. I carried out regular site inspections to verify fabrication compliance with design of the piping system and structural steel.

Draugen PWRI

Assigned to mechanical static team to assess the produced water piping system for the pressure surge transient caused by a choke valve. I was involved in Pipenet simulations model verification to establish magnitude of the force generated at failed pipe support against my own calculations. I performed pipe stress analysis using CAESAR II to check piping and pipe support integrity for the pressure transient. Modal analysis indicated flexibility greater than DNV recommendations. Consequently, I performed FIV fatigue checks to verify the piping system did not require stiffening with focus on small bore connections.

Linnorm – Feed design

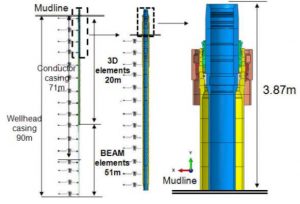

Responsible for the technical assurance of the wellhead fatigue analysis of the Linnorm wells with specific focus on butt welds, fillet welds, connectors and geometrical transitions (notches).

I presented the Shell’s experience on Prelude WH fatigue at a conference organised by PTIL in Stavanger on this subject. Consequently I was assigned as Company representative on wellhead fatigue JIP managed by DNVGL. In addition I was responsible for coaching a graduate intern on fishing protection load re-assessment for Norwegian waters where the mass of the equipment is greater than in UK.

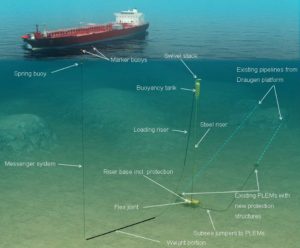

Draugen Oil Export Project – detailed design

Lead structural engineer working on the novel subsea loading system. Responsible for the technical assurance of the system components. Involved in model testing and result interpretation at Marintek. Design and installation analysis review for all components including 152m 24” rigid riser submerged tow and upending calculations to limit fatigue damage. Responsible for non-linear FE analysis in Ansys of forged T connecting the rigid riser to the riser base to verify the designer’s calculations. Author of several technical notes addressing design issues for TA endorsement. Responsible for the delivery of the qualification of the complete loading system to DNV-RP-A203. Site inspections during FAT to ensure compliance with procedure related to lifting operations. Responsible for decommissioning calculations and procedures of the old loading FLP right up to cutting up of the structure in Stord yard.

Ormen Lange Future Compression – Conceptual study

Assigned to front end group I worked on evaluation of various floater concepts for Ormen Lange Future compression, as part of alternative concepts to the base subsea compressor station concept.

The evaluation considered storage capacity, drilling/ work over capability, marine motions, mooring systems, riser restriction, technology maturity, various riser systems & their suitability for OL, modular vs integrated topsides, fabrication and integration to name the few. Upon selection of TLP as base case option to be worked in parallel with subsea solution, I organised the geophysical & geotechnical survey with sub-bottom profiling to establish upper soil thickness and confirm location selection. Overall, this assignment has given me really good insight into the drivers for concept evaluation phase of the project from operator’s perspective.

Draugen Redevelopment Feasibility & Concept Study

Responsible for development of various layout concepts and associated assessment of platform structural integrity for increased loading using SESAM. Performed platform offshore survey for proposed LQ extension. Presentation of results at VARs. Nominated as TA2 for Draugen GBS to engage with the PSA on structural integrity issues related to the ringing response of the platform.